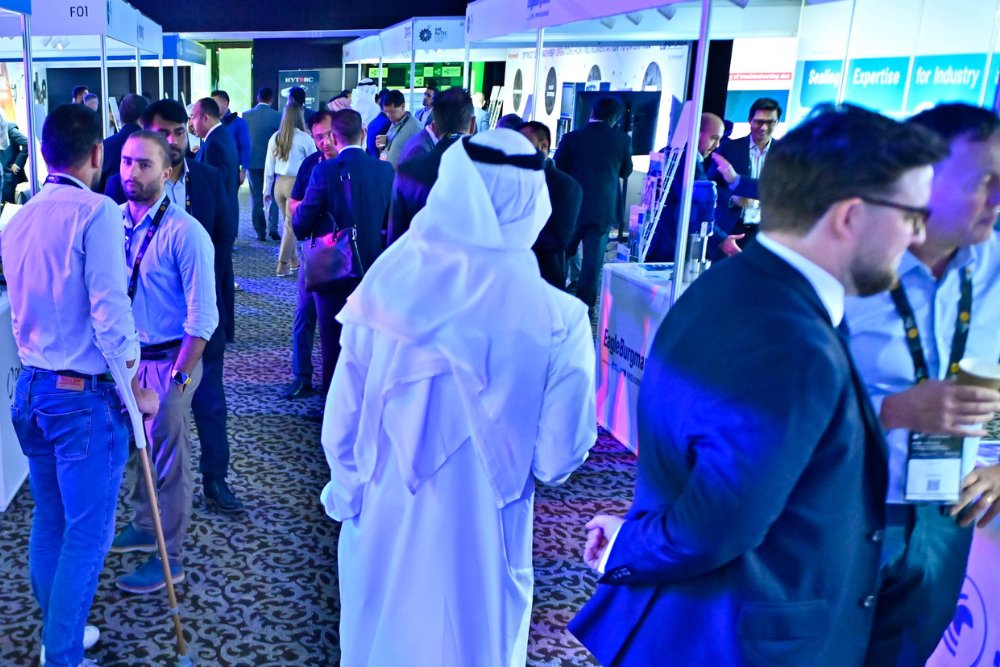

RoTIC Symposium, the Middle East’s premier event on Rotating Machinery Technology, takes place September – 2026 at Grand Hyatt, Dubai. It unites Oil & Gas leaders to explore innovations and drive collaboration.

The event highlights innovations in energy and maintenance driving Net-Zero goals. Join as a Sponsor, Exhibitor, Speaker, or Delegate to get involved.

The RoTIC Symposium Executive Committee is a dedicated group of industry leaders and technical experts guiding the vision, content, and strategic direction of the event. Their collective experience ensures the symposium delivers high-value insights and fosters impactful collaboration in the field of rotating machinery and innovation.

The RoTIC Symposium will feature a lineup of technical conferences inviting leaders and policymakers addressing challenges and opportunities in the field, focusing on efficiency, sustainability, and reliability.

This brochure is tailored for industry experts, maintenance managers, and service providers, providing in-depth insights to enrich your experience at this groundbreaking expo. Download it now to join the dynamic community and make a significant impact in the oil and gas sector.

Don’t miss the opportunity to elevate your brand and position yourself as a favorite among industry suppliers. Contact us today to explore sponsorship opportunities and secure your place at RoTIC Symposium!

Откройте для себя разнообразие игр и провайдеров, от слотов до живых дилеров, на пин ап официальный сайт, где вас ждут увлекательные бонусы и профессиональный подход.